The M1 Garand is a semi-automatic rifle used as a service rifle in the US military during World War II and later Korean War. It was capable, accurate, could be reloaded rapidly, and was a rifleman’s rifle. It was designed by John Garand, a Canadian-American designer, in .30-06 Springfield caliber. It was the first standard-issue autoloading rifle for the United States.

Introduction

At the time, when it was seen as the ultimate rifle in the United States arsenal, legendary General George S. Patton called it “the greatest battle implement ever devised.” M1 Garand entered service in 1936, after succeeding the M1903 Springfield. The selective-fire M14 rifle succeeded the M1 Garand on March 26, 1958.

During World War II, the M1 Garand’s semi-automatic operation gave United States infantrymen a significant advantage in firepower and shot-to-shot recovery time over enemy infantrymen armed primarily with bolt-action rifles.

It is one of the most iconic US firearms and was produced in vast numbers. Although it was certainly not the first self-loading service rifle ever fielded, there is little doubt that the M1 Garand was the weapon most responsible for validating that concept in operational service.

Development

Development of what became the M1 Garand began in the 1920s, following several US Army evaluations of many rifles designed by renowned firearms engineer John C. Garand and numerous competing models made by Berthier, Hatcher-Bang, Thompson, and Pedersen. The finalists were the M1924 Garand and the Peterson T1, each offered in two calibers; the .30-06 Springfield (7.62×63 mm) round already used by the US armed forces and the new .276 Pederson (7×51 mm).

Both rifles performed well in .276, but the .30-06 Pederson T1 was sub-par, and the .30-06 M1924 Garand was disqualified. The best performing rifle was the M1924 Garand in .276 (designated T1E1), and it was declared the winner — however, US Army Chief of Staff Gen. Douglas MacArthur intervened directly. It forbade the acquisition of the .276 Pederson round on the grounds that the US Army still had a large stockpile of .30-06 ammunition.

The .276 M1924 had to be modified back into .30-06, in a process that wasn’t completed until 1933 and was re-designated as the T1E2. However, numerous problems occurred with the M1924 field testing in 1934, forcing John Garand to return to the drawing board again. The corrections finally paid off, and the Army cleared the M1924 for service on November 7th, 1935, and formally type-classified it as the M1 Garand on January 9th, 1936. Though the development of the M1 Garand was finally complete, introducing it into production soon proved problematic, and several components had to be modified for assembly line construction.

Production

Production began at a rate of only ten rifles per-day in 1937, though the first deliveries occurred in September of that year, with production increasing to 100/day by 1939. Further changes were implemented in 1940, not only to improve the weapon but also to further increase the production rate. Despite these efforts, many rifles had to be recalled as defects not identified in testing began to surface in operational use, notably, problems with the “gas trap” grenade-launching system. Though by the end of 1941, M1 Garand production exceeded 600 rifles/day, and the US Army had almost entirely replaced their preceding rifles.

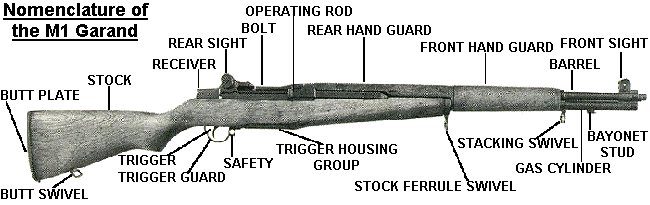

Design

The M1 Garand rifle is a .30 caliber, gas-operated, 8-shot clip-fed, semi-automatic rifle. The M1 Garand’s safety catch is located at the front of the trigger guard. It is engaged when it is pressed rearward into the trigger guard and disengaged when it is pushed forward and protruding outside the trigger guard. The rifle was designed for simple assembly and disassembly to facilitate field maintenance. It can be field stripped (broken down) without tools in just a few seconds.

The metallic portions of the weapon are made entirely of steel. The receiver is made from drop-forged steel, as is most of the barrel assembly, but the gas tube is made of stainless steel. Several types of wood were used for the M1 Garand’s furniture, though the two most commonly used were Birch and Walnut. The rifling is a conventional groove-and-land type, with a right-hand twist of 1-in-10 inch (254 mm). Early model rifles have four grooves, while late models have only two grooves.

The buttstock is hollow and contains a cleaning kit accessible via a hinged, spring-loaded door on the butt plate. While most of the M1 Garand’s metallic components are parkerized with a dark finish, this was impossible to apply to the gas tube made of stainless steel. The gas tube was thus usually stove-blackened or painted to reduce its reflectivity, though this finish often wore off quickly in the field. However, many M1s made especially for ceremonial use or sale to civilians also have lighter finishes.

The rifle had an iron sight line consisting of rear receiver aperture sight protected by sturdy “ears” calibrated for 100–1,200 yd (91–1,097 m) in 100 yds (91 m) increments. The bullet drop compensation was set by turning the range knob to the appropriate range setting. The bullet drop compensation/range knob can be finely adjusted by setting the rear sight elevation pinion.

The elevation pinion can be finely adjusted in approximately 1 MOA increments. The aperture sight was also correct for wind drift operated by turning a windage knob that moved the sight in around 1 MOA increments. The windage lines on the receiver indicated the windage setting was 4 MOA apart. The front sighting element consisted of wing guards protecting the front post.

En bloc clip

The M1 rifle is fed by an en bloc clip which holds eight rounds of .30-06 Springfield ammunition. The rifle ejects the clip and locks the bolt open when the last cartridge is fired.[40] The M1 is then ready to reload. Once the clip is inserted, the bolt snaps forward on its own as soon as thumb pressure is released from the top round of the clip, chambering a round and leaving it ready to fire.

By modern standards, the M1’s feeding system is archaic, relying on clips to feed ammunition, and is the principal source of criticism of the rifle. Officials in Army Ordnance circles demanded a fixed, non-protruding magazine for the new service rifle. At the time, it was believed that US soldiers would easily lose a detachable magazine on a general-issue service rifle (a criticism made of British soldiers and the Lee–Enfield 50 years previously), and would render the weapon too susceptible to clogging from dirt and debris (a belief that proved unfounded with the adoption of the M1 Carbine), and that a protruding magazine would complicate existing manual-of-arms drills.

As a result, inventor John Garand developed an en bloc clip system that allowed ammunition to be inserted from above, clip included, into the fixed magazine. While this design provided the requisite flush-mount magazine, the clip system increased the rifle’s weight and complexity and made only single-loading ammunition possible without a clip.

Gas system

The M1 Garand is gas-operated, with a rotating bolt that has two locking lugs, and the gas tube is piston-actuated with a long stroke gas piston. It is not a selective-fire weapon and will only produce a single shot with each trigger pull. The safety switch is located on the front of the trigger group; it safes the weapon when toggled rear (inside the trigger group) and unsafe the weapon when toggled forward (outside the trigger group).

The gas tubes in pre-1940 M1 Garands had gas traps, which proved excessively expensive, maintenance-intensive, and unreliable; these were replaced in all subsequent rifles with much simpler gas blocks, though this also made the weapon slightly heavier and more front-heavy.

Ammo

The primary munition for the M1 Garand is the M2 Ball, a type of Full Metal Jacket round. The penetration and stopping power of the M2 Ball round are immense compared to modern assault rifle ammunition, and at a range of around 50 meters, it will penetrate 12.7 mm of mild steel; at about 200 meters, it will penetrate 914 mm of solid Oak wood. Given this performance, it’s understandable why the US military was reluctant to abandon the .30-06 round.

The M2 armor-piercing round naturally has much better penetration performance and is rated to penetrate 22 mm of rolled homogenous armor at around 100 meters; the M14 armor-piercing incendiary round has the same penetration but also a pronounced incendiary effect. The M25 tracer round could also be fired from the M1 Garand, though they were usually only fired from machine guns. A variety of .30-06 blanks, dummy, and match rounds were also available.

Many M1 Garands were later converted to fire 7.62×51 mm NATO instead of .30-06, notably those operated by the US Navy and the armed forces of Italy and Argentina. While both rounds share many qualities, the differing trajectory and shorter reach of 7.62×51 mm NATO eventually necessitated new sights. Moreover, the US Navy had attempted to use an insertable chamber adaptor for the otherwise standard M1 as a shortcut to avoid having to replace the entire barrel. Still, without success, they eventually had to replace the barrels anyway.

Devastating. 30.06 ball ammo penetrates walls, doors, tree trunks, car bodies, tires, cinder blocks, barrels, helmets, body armor, and even the skin of some lightly armored vehicles. It has the reach and punches with an effective range of over 1000 yards and a maximum range of over three thousand yards. The round at over 200 yards can produce hydro-shock effects, with a solid hit on the human torso.

Additional equipment

The M1 Garand accepts a variety of bayonets, though the most commonly used model since the Korean War (and the last designed especially for the M1) is the M5. This dagger-like bayonet has a 152 mm long blade with a spear point, a 152 mm long edge on the front of the blade, and a 76 mm edge on the back. A push-button release allows the M5 to be fixed or removed from the M1 in seconds without using any tools.

The M5 cannot be used on rifles other than the M1 Garand and some of its derivatives. The M1905 bayonet (with a much longer 406 mm blade) made for use on the old M1903 bolt action rifle was also compatible with the M1 Garand and was the primary bayonet for the M1.

Also usable on the M1 Garand was the M7 grenade launcher and the accompanying M15 sight used to aim it. The launcher is fitted to the weapon’s muzzle, and the M3 Grenade cartridge (a blank round made especially for this purpose) is used to launch the projectile. Various grenades were fielded for the M7, including HE-FRAG, HEAT, and smoke, with an effective range of approximately 350 meters. Though these are safe to launch from a shouldered rifle in standing, kneeling, and prone positions, the preferred position was with the butt of the M1 Garand against the ground and the grenade aimed at a high angle, not unlike a mortar.

Particularly notable is the M1 rifle grenade adaptor, a projectile that could hold a variety of regular hand grenades, effectively turning them into rifle grenades. Though the M1 rifle grenade adaptor had the obvious advantage of allowing a grenadier to carry lighter munitions that could be thrown if necessary, it could also create a somewhat awkward situation with the blank cartridge misfired. The spoon fell off – or if the grenade was accidentally fired into an enemy fighting position before the pin was removed.

Users

The M1 was produced in staggering numbers, exceeding 5.5 million rifles during World War 2 and growing to over 7 million with post-war production. They were manufactured in the US by many companies, including Springfield Armory, Winchester, Harrington & Richardson, and even International Harvester; the latter firm alone produced 337 623 M1 Garands. Additional US manufacturers produced the M1 after the war, primarily for the civilian market, and foreign manufacturers such as Beretta and Breda continued to produce them for some time.

Many nations have operated the M1 Garand, as the US supplied millions of surplus examples to allies and favored states for decades following World War 2. Known users include Argentina, Brazil, Cambodia, Canada, China, Cuba, Denmark, Ethiopia, France, West Germany, Greece, Indonesia, Iran, Israel, Italy, Japan, Jordan, Laos, Liberia, Norway, Pakistan, Panama, Paraguay, the Philippines, Saudi Arabia, South Korea, South Vietnam; Taiwan; Thailand; Turkey; United States; Uruguay and Venezuela.

Variants

The M1 Garand is not to be confused with the M1 Carbine (though it complemented the Garand in service) or the Johnson M1 rifle (a competitor of the M1 Garand). That both firearms use the same stock number and their very different chamberings are both usually described only as “.30 caliber” had only added to the confusion over time.

M1924 Garand

Forerunner for the M1 Garand went through many design alterations before being accepted by the US Army as the M1 Garand. Did not enter production or service.

M1 Garand

Basic production model. The proportions differed slightly with each manufacturer, and 1930s models had tubes with gas traps, while all produced since then have gas blocks.

T26

A shorter version of the M1 Garand with a 457 mm (18″) barrel and a folding buttstock; as it was intended primarily for use by armored vehicle crews, it was informally called the “Tanker Garand.” It did not enter production, but some prototypes saw combat during the Battle of the Philippines in 1941-42.

M1C

Sniper rifle variant of the M1 Garand, with provisions for mounting an M84 telescopic sight. The M1C is one of the rarest production variants, with 7 971 produced in the 1940s and a further 4 796 during the Korean War.

M1D

This is an improved M1C, with a flash hider and a new scope mount. The M1D program was initiated after World War 2, but its development was long, and few had been issued in time to see much combat in the Korean War. Just 21 380 M1Ds were produced, making it a coveted collector’s item today.

MC52

Shorthand for “USMC 1952 Sniper’s Rifle” was an even further development of the M1 Garand into a sniper rifle. Its tenure with the US military was brief, having arrived too late to see any notable action in the Korean War and being quickly supplanted in the early 1960s by bolt-action rifles.

Type 4

Japanese self-loading rifle based on the design of the M1 Garand. It was re-chambered in 7.7×58 mm Arisaka and held a larger 10-round fixed magazine. Interestingly, this magazine had to be charged with stripper clips rather than En Bloc clips, and only 5-round clips were provided for this purpose. Only a few hundred were completed by the end of World War 2, and Type 4 never saw operational service.

T47

The last in a series of development of the M1 Garand, in an attempt to evolve it into an assault rifle, the T47 was a selective-fire weapon chambered in 7.62×51 mm NATO (note that the T47 was the first firearm ever to fire this round), with a rate of fire of 700 rpm, and a detachable 20-round box magazine. It was selected to replace the M1 Garand and, after further development, became the M14.

M14

Also developed by Springfield Armory, the M14 was the successor to the M1 and was an evolution of the aforementioned M1 variant. This weapon was the ultimate evolution of the M1 Garand, and it saw widespread service. The M14 is a selective fire weapon capable of semi-automatic and full-automatic firing.

Beretta BM-59

Developed in Italy, the BM-59 is a direct conversion of the M1 Garand pattern into a selective-fire assault rifle. It resembles the M14 and is also chambered in 7.62×51 mm NATO and fed by a 20-round detachable box magazine. The BM-59 was surprisingly successful in service, being used by Italy for several decades, exported to several other nations, and even produced under license in Indonesia as the SP-1.

Mini-14

Civilian semi-automatic rifle based on the M1 Garand produced by Ruger from 1973 onward. It is a miniaturized M1 Garand in .223 Remington feeding from a detachable box magazine, despite its name’s a deliberate reference to the M14.

Mini-30

Mini-30 is a Mini-14 re-chambered in Soviet 7.62×39 mm ammunition.

AC-556

The military version of the Mini-14 is a 5.56×45 mm NATO with a selective fire capability. Also, some M1 Garands were re-chambered in .303 Lee Enfield during World War 2 (these particular rifles are now prized collector items). From the 1950s onward, countless examples were converted to fire 7.62×51 mm NATO instead of .30-06. Examples produced for civilians may have been chambered for other rounds as well.

Technical specifications

| Country of origin: | United States |

| Manufacturer: | Springfield, as many others through the years |

| Entered service: | 1937 |

| Caliber: | .30-06 Springfield (7.62×63 mm) |

| Weight (unloaded): | 4.31 kg |

| Weight (loaded): | 5.1 kg |

| Length: | 1 100 mm |

| Barrel length: | 610 mm |

| Muzzle velocity: | 853 m/s |

| Practical rate of fire: | 14 – 24 rpm |

| Magazine capacity: | Eight rounds |

| Sighting range: | 1.097 m |

| Range of effective fire: | 457 m |